A Deep Dive Into Germany's Submarine Force

Matus Smutny, a features contributor to The War Zone, had a unique opportunity to visit the German Navy’s submarine base and its state-of-the-art hunter-killer submarine fleet. The resulting feature provides a deep dive into the Type 212A class submarine and its operations.

Here is his report:

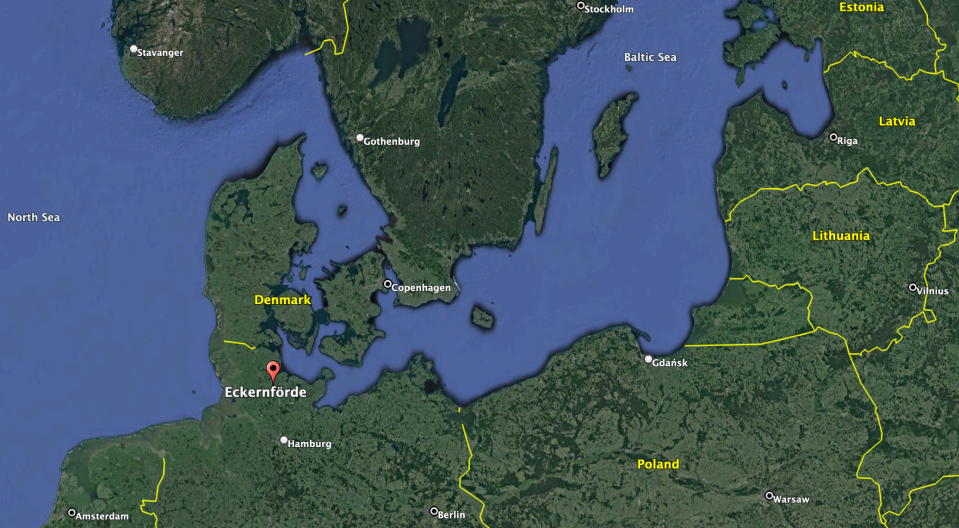

The War Zone’s visit to the German Navy’s 1. Ubootgeschwader (1. UG, or 1st Submarine Squadron) at Eckernförde, in northern Germany, began with a meeting with the base commander, Lars Goessing, before getting a remarkable insight into the German Navy’s submarine force and its technologies.

Type 212A: hunter-killer of the Baltic Sea

Before looking in detail at the Type 212A, it’s important to acknowledge the specific design requirements behind this submarine.

Germany’s historic ‘home area’ of submarine operations is the Baltic Sea, which is notably shallow and confined.

For West Germany, the main task during the Cold War was very simple — it was about forward defense, so the submarine's job would have been to attack any opposing, mainly amphibious forces heading west.

This led to the development of small, but very capable diesel-electric submarines able to transit covertly in areas with a water depth of less than 25 meters (82 feet) and operate in an environment with a potentially high density of anti-submarine warfare (ASW) forces and naval mines. In the days of the Cold War, West German submarines were limited to the Baltic Sea, and the submarines were therefore designed for this specific environment.

The peculiarities of the Baltic Sea meant that extensive research and development were necessary to develop submarines for this operating environment.

The limitations in terms of submarine size were due to both the geography of the Baltic area and post-war limits that specified a maximum submerged displacement of 500 tons. This led to the development of extremely effective systems and the German Navy still benefits from the fact that Germany’s defense industry can design very economical and compact equipment for its submarines. As a result, German-designed submarines are smaller than equivalent submarines from other nations with the same performance.

Other requirements that arise from the Baltic region include good depth-control properties, which means that even today, German submarines can operate in very shallow waters, of around 20 meters (66 feet), or even less.

With the development of the Type 212A class submarines, Baltic operations were again considered, but these boats have also grown quite significantly compared with their predecessors. The background to this growth is the improvement of living conditions for the crew on board and the need to provide an air-independent propulsion (AIP) drive.

The Type 212A is the first conventional submarine class with fuel cell propulsion, which can operate independently of the outside air for a prolonged period — this has proved to be an outstanding advantage for conventional submarines, as we have discussed in the past. Today, the area of operation of the German submarines still focuses on the Baltic Sea, as well as the Norwegian Sea, the European waters of the Mediterranean Sea, and the North Atlantic. In principle, however, German submarines can be deployed anywhere in the world.

The Type 212A class is perfectly tailored to its dedicated purpose as originally planned and designed in the last years of the Cold War; the requirements being very good signatures (acoustic, radar, magnetic, etc.), small size, and outstanding depth control characteristics. The need for covert operations with reduced indiscretion rates ultimately led to the development of state-of-the-art AIP technology.

State-of-the-art non-nuclear submarine technology

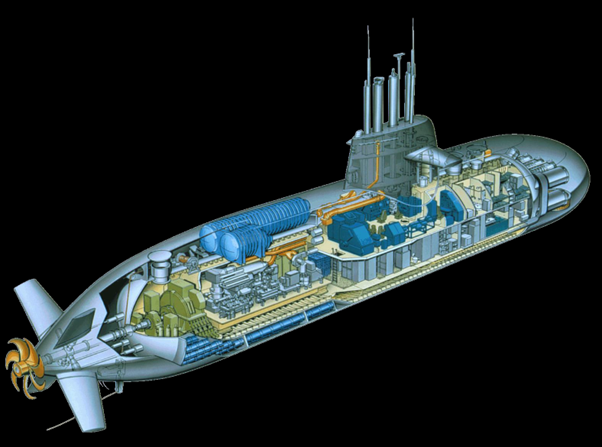

The Type 212A class submarines feature a one-and-a-half-hull configuration, with the pressure hull made from non-magnetic steel.

In total, six hulls were built by Howaldtswerke-Deutsche Werft GmbH (HDW) in Kiel and Thyssen Nordseewerke GmbH (TNSW) in Emden, Germany, for the German Navy. Another four hulls were completed for the Italian Navy, as the Todaro class, built by Fincantieri at the Muggiano shipyard.

Type 212A class submarines were built in two major production blocks: Batch I and Batch II, for both the German and the Italian navies:

Batch I, German Navy: U-31 (S-181), U-32 (S-182), U-33 (S-183), and U-34 (S-184)

Batch I, Italian Navy: Salvatore Todaro (S-526) and Scirè (S-527)

Batch II, German Navy: U-35 (S-185) and U-36 (S-186)

Batch II, Italian Navy: Pietro Venuti (S-528) and Romeo Romei (S-529)

https://twitter.com/Saturnax1/status/1665590189513756673?s=20

The main difference between the batches is the larger sail on the German Batch II boats that houses a four-person lockout chamber for special operations forces, a mast for the Callisto UHF, a VHF and GPS communications buoy, an extended flank sonar array, as well as a set of external hull mounts for various special operations containers and equipment. Apart from the lockout chamber, special forces operators can also use the free-flooding space in the sail for covert insertion operations.

The Italian Navy’s Batch I and II boats are almost identical but are able to externally mount a special operations hangar on the aft deck or a cradle for a swimmer delivery vehicle (SDV).

Future developments of the Type 212A design include:

Type 212A NFS for the Italian Navy: NFS (Near Future Submarine), or Todaro Batch III is a planned batch of four hulls with specifications similar to the German Navy’s Batch II class. The major upgrade will be the use of lithium-ion batteries instead of the old lead-acid batteries. This has the potentially to dramatically increase the dive time of performance of AIP operations. The capability to use submarine-launched cruise missiles (SLCM) is also planned. The construction of the first Type 212A NFS class boat commenced at the Muggiano shipyard in La Spezia in January 2022.

Type 212CD for the German Navy: CD (Common Design) is a further refinement of the Type 212A with an improved propulsion system including a next-gen AIP system, new-generation batteries (most likely of the Lithium-Ion type), improved diesel generators, increased speed and range, improved self-defense capabilities, and improved signatures and target echo strength thanks to a specially designed hull shape. Two Type 212CD hulls, U-37 (S-187) and U-38 (S-188) were ordered in 2019 with planned commissioning in 2032 and 2034, respectively.

Type 212CD for the Norwegian Navy: A replacement for the aging Type 210 Ula class diesel-electric submarines, the procurement agreement calls for four submarines with construction expected to start this year.

https://www.youtube.com/watch?v=p4Ld2Ei_wTQ

Even in its basic form, the Type 212A class is one of the most advanced non-nuclear submarines in the world. The external hull is extremely smooth, with streamlined transitions between the hull and the sail. The use of non-magnetic steel for the hull reduces the threat of naval mines and detection by the magnetometers on the magnetic anomaly detectors (MAD) used by ASW assets, e.g. helicopters and fixed-wing aircraft.

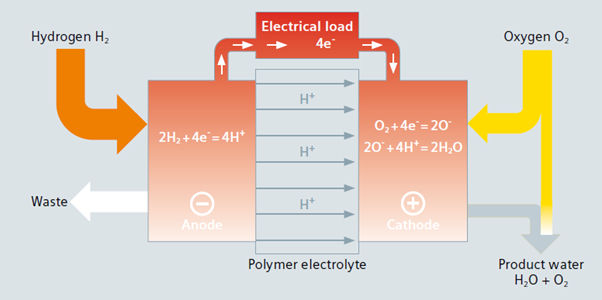

At the heart of each Type 212A class submarine is a unique AIP propulsion system. Older diesel-electric submarines used diesel engines coupled to electric generators to charge their batteries, which powered an electric motor turning the propeller shaft. The Type 212A’s AIP system generates energy in a series of Siemens PEM (Polymer Electrolyte Membrane) fuel cells, where a chemical reaction between hydrogen and oxygen generates electricity for the electric motor and for the batteries. The waste product of the fuel cells’ powerplant is water that is collected and used for e.g., toilet flushing. The tanks for the liquid oxygen and hydrogen are located outside of the pressure hull, right under the outer free-flooding hull.

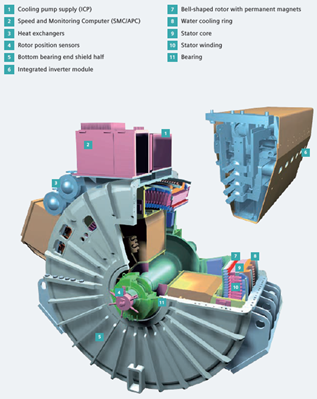

The PEM powerplant and batteries supply power for the Siemens Permasyn electric propulsion motor — a remarkable piece of naval engineering.

The Siemens Permasyn is a very compact, freshwater-cooled synchronous motor, with integrated inverter modules. By changing the inverter control setting, the phase currents and thus the torque of the motor can be varied infinitely over the entire operating range. The power output is approximately two megawatts, and the engine can be operated at a torque of 110 percent of the rated value for a maximum period of two minutes. The motor can be operated in three modes:

Normal (automatic) mode, controlled by the automatic propulsion controller (APC) unit.

Manual with output power restricted to approximately 50 percent of the nominal power.

Turning mode allowing very slow propeller shaft turning for inspection purposes.

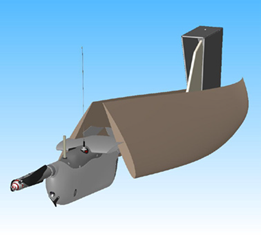

The Siemens Permasyn drives a single propeller shaft with a seven-bladed skewed propeller with a propeller boss vortex diffuser (PBVD) that improves performance and reduces propeller noise. The technology behind the PBVD is something you can read more about here.

Each Type 212A class submarine also features a single MTU 16V 396 2.1-megawatt diesel engine used for surface transits and if needed for recharging the batteries.

The electronic systems include an STN Atlas sonar suite with several specific sensor arrays, optronic scopes, and a Kongsberg combat system.

Armament consists of six 533-millimeter torpedo tubes able to launch DM2A4 Seehecht heavyweight wire-guided torpedoes, as well as the IDAS (Interactive Defence and Attack System), a medium-range surface-to-air missile with anti-ship and land attack capabilities, which remains in development. There are also externally mounted belts for up to 24 naval mines.

One of the interesting concepts that didn’t make it beyond the concept phase was the Triple-M system. Triple-M (Modularer Mehrzweck-Mast) is a hoistable modular system developed by GABLER Maschinenbau. This two-stage, multi-purpose mast allows the fast exchange of payload modules, such as:

Muraena Rheinmetall RMK-30, a remotely controlled, recoilless 30mm cannon. The RMK-30 would give the submarine the ability to engage low-flying aircraft, drones, and small surface vessels. The Muraena system uses radar guidance and periscope sights to aim the cannon and can effectively engage targets up to a range of around 1.8 miles.

GABLER VOLANS (Verdeckte Optische Luft-Aufklärung Navalisiertes System), a drone launch system able to store and launch up to three folding-wing ALADIN UAVs, a type originally developed for the German Army. The ALADIN can be used for daytime/infrared reconnaissance and for target identification.

Various mission-specific ELINT/COMINT/ESM antennas and jamming equipment designed by GABLER & FS-Antennentechnik GmbH (FSA).

Twenty-five years since the first hull was laid down, the Type 212A class is still considered to be among the best non-nuclear submarine designs in the world. Post-war size limitations and Cold War-era experience in the shallow Baltic Sea gave the German Navy a unique chance to develop cutting-edge technology packed into a relatively small hull. The near-silent AIP propulsion, X-shaped rudders, use of non-magnetic steel, a massive array of active and passive sensors, and highly trained crews make the Type 212A an extremely potent platform for ASW and anti-surface warfare (ASuW). The design is also equally capable of special operation forces (SOF) insertion and covert ISR littoral missions, of the kind that would be impossible to directly achieve with larger, nuclear-powered submarines.

The Commander

Born in 1979, Lars Goessing, commander of the 1. Ubootgeschwader, joined the German military in 1998, and his career began on fast patrol boats, followed by minesweepers, although he always had the dream of becoming a submariner.

“The idea to operate undersea with a small crew, to be on your own without a squadron commander being always present, was something I also wanted to do,” Goessing told The War Zone, in an exclusive interview. “I wanted to become a part of this highly professional squadron and especially a submarine crew. I entered the submarine service just after my graduation from university and having finished my Naval Officer basic training.”

Goessing began his submarine career onboard the Cold War-era Type 206A class diesel-electric submarine U-23 (S-172) as a Weapons Officer, becoming an Executive Officer after one year. His next posting was to the more modern Type 212A class U-33 (S-183) in 2009.

After finishing the demanding Command Course (nicknamed ‘The Perisher’) in 2011, Goessing took command of Crew Charlie and later Crew Delta on board the Type 212A class U-31 (S-181). During his time as CO, he also spent time above the waves, aboard the Brandenburg class frigate Bayern (F-217) with the Standing NATO Maritime Group 2 (SNMG 2) staff. As he says: “It was a great experience for a submariner to serve on a surface vessel; you are normally only observing via periscope.”

In 2014 Goessing completed the Admiral Staff Course in Hamburg and became the head of the Submarine Training Facility in Eckernförde, followed by appointments in the defense ministry in Berlin and NATO HQ in Brussels, where he was responsible for EU Missions and Operations as a Desk Officer for the German NATO Military Representatives.

On June 30, 2022, Goessing was appointed Commanding Officer of the German submarine force, when he took responsibility for the 1st Submarine Squadron in Eckernförde.

A video of the Type 212A class U-31 (S-181), commanded by Captain Lars Goessing, making a surface transit in very rough weather:

https://www.youtube.com/watch?v=1wvCwEeDOJo

“Being the commanding officer of the German submarine force is such an honor,” Goessing explains. “We are more than submarines: our AGIs [intelligence-gathering ships], our Submarine Support Unit, and our land-based sections of the squadron form a unique and strategic installation of the German Navy. We are constantly improving and developing new detection procedures. By sharing with our German Navy friends on the surface, we create important synergies. Our knowledge and network are constantly growing.”

Inside the 1st Submarine Squadron

The 1. UG was formed on October 1, 1961, in Kiel, and was declared operational at the beginning of September 1962. The squadron was assigned its first boat with the commissioning of the Type 201 class U-1 (S-180) on March 21, 1962 — this was the first submarine built in West Germany and was followed by many more units in the following years.

Apart from the six Type 212A class submarines, the 1. UG currently operates also following surface vessels:

Type 423 Oste class: SIGINT/ELINT/long-range reconnaissance (AGI) ships Alster (A-50), Oste (A-52), and Oker (A-53)

Type 404 Elbe Mod class: Submarine support (ASL) ship Main (A-515)

Over the years, several other naval units have been assigned to the 1. UG structure:

Submarine Training Center (SUBTNGCEN, Ausbildungszentrum Uboote, AZU)

Hydroacoustic Analysis Center of the German Navy (HAC, Hydroakustisches Analysezentrum der Marine, HAM) and Marine Coast Station Marienleuchte (Marineunterwasserortungsstelle, MUWOSt)

Squadron Staff

System Support Group

The Training Process

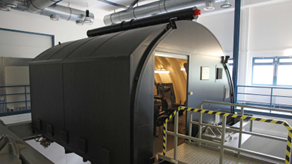

A tour of the training facility provided clues as to what it’s actually like aboard a modern diesel-electric submarine, with stationary simulators for the Type 212A Batch I and Batch II classes faithfully representing the size and equipment layout of the real submarine. Very quickly it becomes clear just how extremely compact a modern diesel electric submarine’s command center is.

The training facility also includes a fully functional diesel engine of the same type as installed on the submarines and a full-sized battery compartment simulator. The battery simulator teaches operators how to check and maintain the batteries. This engineering space is even more constrained, with the operator using a movable platform above rows of batteries, with just a few centimeters of free space available. Completing this task during a surface transit on a choppy sea would clearly be a challenge.

But the highlight of the training center is the diving simulator. As with the static simulators, this is a true copy of the Type 212A class command center. Once the doors shut behind you, it takes only a few minutes before you feel like you’re in a real submarine. The simulation of the full dive and emergency ballast-blow procedures really gives you an idea of how much the submarine pitches during such maneuvers. Were it not been for the safety belt, I’d most likely have been airborne.

All of this led up to the main event: a tour aboard the Type 212A Batch I class submarine U-32 (S-182).

The crew on the deck stood at attention and gave a readiness report to the commander. While the Type 212A class is a relatively small-sized submarine, it’s still larger than it may seem in the accompanying photos and clearly a marvel of naval engineering.

The Submarine Training Center traces its roots back to August 1, 1959, when it was formed as the Submarine Training Group (Ubootlehrgruppe, ULG) in Eckernförde before moving to Neustadt in Holstein on August 31, 1960. On August 31, 1989, the ULG was reconfigured as the Submarine Training Center (AZU) and returned to Eckernförde. Following a realignment of the German Armed Forces on August 29, 2013, the Submarine Training Center was incorporated into the 1. UG structure.

The Submarine Training Center includes several facilities that provide complete tuition for the crew, as well as continuous support.

Basic Training includes a course-based preparation period in which the crew learns their onboard tasks. This includes ashore and onboard training, classroom training, simulator training, and computer-based training.

Crew and Operational Training prepares the crew for command tasks, damage control, and weapons employment. These modules are carried out in simulators, onboard, including in formations, and end with a final ‘combat ready’ approval.

The training center also provides bespoke teaching for partner navies’ submariners, offering them onboard training, classroom training, simulator training in English, and support during their initial crew training.

The typical crew training schedule is divided into three major sections:

CIC Training 1 and pier-side training module — once finished, the crew receives a ‘Safe to Sail’ certification.

CIC Training 2 and sea training 1 and 2 modules — once finished, the crew receives a ‘Limited Combat Ready’ certification.

CIC Training 3, sea training 3, international exercise, and torpedo launch exercise — once finished, the crew receives a ‘Combat Ready’ certification.

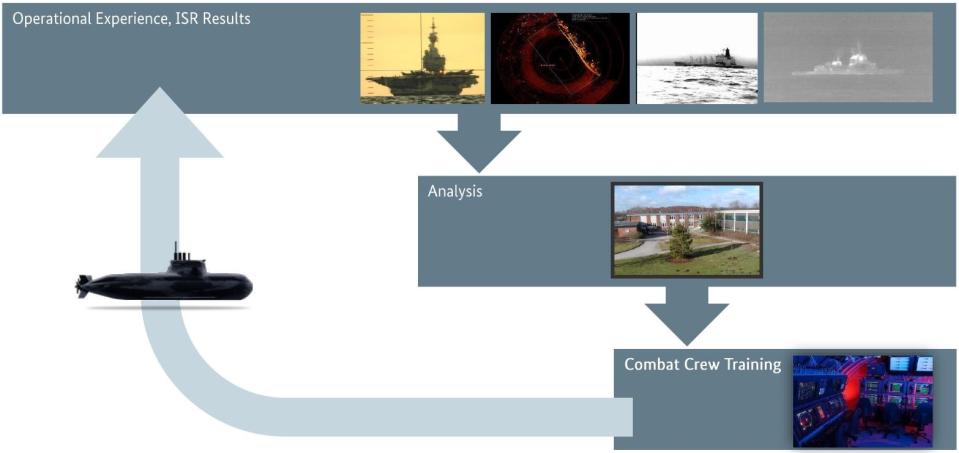

But the learning process doesn’t end after the crew receives the final certificate. The Hydroacoustic Analysis Center (HAC) continuously analyses huge amounts of data gathered from operational experience and uses intelligence, surveillance, and reconnaissance (ISR) methods. After analyzing it, the results are fed into the combat simulators, so that the crews are trained with the latest data.

One of the sources of the underwater acoustic data for the HAC is the Marine Coast Station Marienleuchte. This reconnaissance facility was used during the Cold War to locate submarines and other seagoing vessels in the Baltic Sea and to intercept military communications.

In 2006, Marienleuchte was assigned to the Submarine Training Center and received several technological upgrades to its systems. The aging Cold War-era underwater surveillance systems — Holzauge (Wooden Eye) and the U.S.-made Miss Beta — were replaced with the Große Seeohr (Great Abalone/Sea Ear) system consisting of three acoustic sensors laid under the Fehmarnbelt shipping route.

Apart from these underwater systems, the station also operates a DWQX-12 passive sonar system that was put into operation in January 1993, after receiving funding from NATO. The passive sonar provides excellent bearing accuracy for detected vessels with extensive recording and analysis possibilities of the intercepted signals. It also allows detection and classification at relatively long distances.

As noted earlier, the Submarine Training Center features some state-of-the-art submarine training simulators. At the heart of the facility is a massive depth control simulator faithfully imitating all movements and attitudes of a submarine. The simulator is used for training the diving and surfacing procedures as well as emergency scenarios simulating technical failures of any given system of the submarine. The simulator is extremely flexible as it features LCD screens; with a simple upload, it can simulate the controls of nearly all friendly navies’ submarines, e.g., Brazilian, Peruvian, Portuguese, Dutch, and Norwegian subs.

Submarine crews are also trained on two separate Type 212A Batch I class and Type 212A Batch II class control room simulators, and the standalone submarine control systems simulator, fully functional diesel engine, and a full-scale replica of the battery compartment that we described earlier.

The Unique World of the U-Boot

As with every service, the effectiveness of any platform or equipment is not dictated solely by the technology, but mostly by the skilled crew that operates it.

Serving onboard the Type 212A class submarine is unique, as it offers a wide variety of missions in one of the most challenging underwater environments. The crews are highly capable thanks to the dedicated onshore simulators and ongoing training, using the most up-to-date data available. The well-being of the crew and their families is also an important factor, especially within the submarine force, and this is something that Commander Goessing doesn’t underestimate:

“When I come to work, I have a smile on my face. Every day. That’s due to all the proud women and men working in this unique squadron. We care for our soldiers, but we also care for their families as our job is special and requires a lot of understanding. This is not self-evident, and we are all taking this seriously. It’s about every single person in our squadron. The power of our people is reflected by the strength of our units. That’s our most important capital. We need young people who love to work in a highly skilled and professional environment, and who love to serve their country. This is a unique experience!”

https://twitter.com/Saturnax1/status/1652538560409477120?s=20

The upcoming Type 212CD class will bring yet more technological advances compared to the successful Type 212A design. It promises to help the German Navy and its allies control the challenging waters of the Baltic Sea and beyond for decades to come.

The author would like to thank 1. UG Commander Lars Goessing for the invitation to visit Eckernförde and the tour of the Type 212A class submarine U-32 (S-182). Lars Goessing can be found on Twitter as @LGoessing. Another recommended Twitter account with daily news from the 1. UG is @ComDeuSubSqn.

About the author: Matus Smutny is a Senior Lead Engineer in the automotive industry and has a lifelong passion for post-war naval history and technology. He maintains a digital gallery containing more than 148,000 photos and can be found on Twitter as @Saturnax1.

Contact the editor: thomas@thedrive.com

money

money